AG Lubricants is supporting a steel producer with an extensive service offering. Key areas are on-site maintenance, stock level monitoring, breakdown assistance, product rationalisation, and technical consultation.

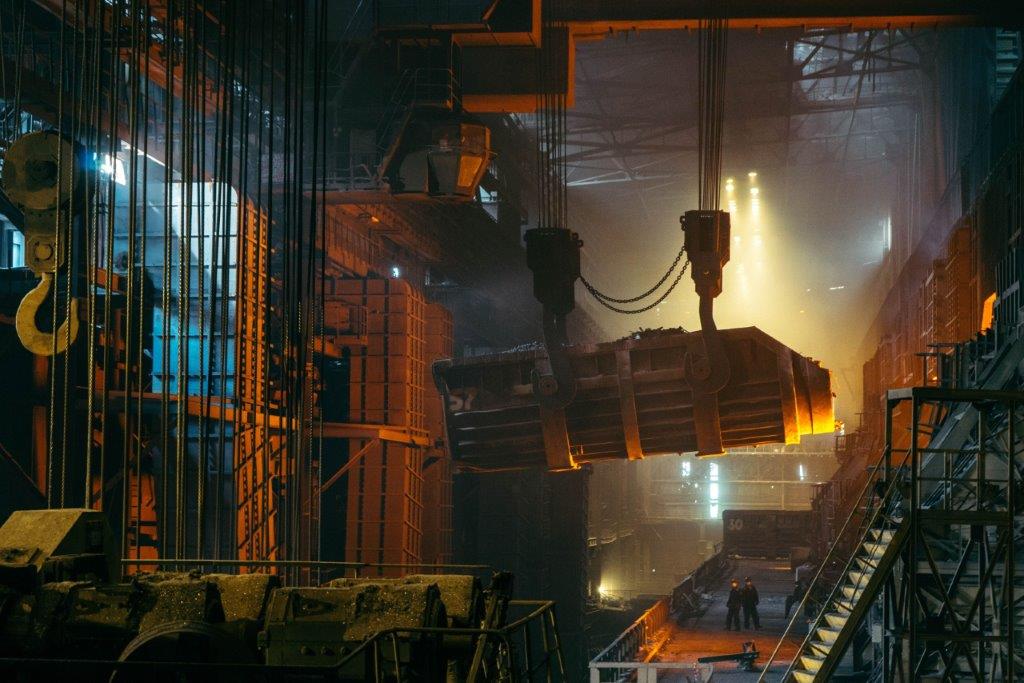

AG Lubricants, a trusted provider of premium lubrication solutions, has partnered with a major player in the South African steel industry to supply high-performance Mobil lubricants, Quaker Houghton industrial fluids, and value-added technical services. This collaboration marks a strategic step toward improving productivity, operational reliability, and long-term efficiency within the steel manufacturing environment.

“We are proud to partner with a leader in the steel industry and support their operations with our high-performance lubricants and advanced technical services,” says Johan Nell, Lubricant Engineer at AG Lubricants. “This partnership reflects our commitment to delivering measurable value and ensuring the continued success of our industrial clients.”

AG Lubricants

AG Lubricants is supporting the steel producer with an extensive service offering, including on-site maintenance, stock level monitoring, breakdown assistance, product rationalisation, and technical consultation, all tailored to meet the rigorous demands of industrial manufacturing.

The partnership began in 2017 and gained momentum following the commissioning of a state-of-the-art hot strip mill, supplied by Danieli. The facility exclusively utilizes OEM-approved Quaker Houghton and Mobil technologies to ensure optimal equipment performance.

To ensure accurate product application and smooth integration, AG Lubricants conducted a detailed on-site audit in collaboration with the client’s engineers and technical teams from Mobil and Quaker Houghton. Improvements included a full clean-up in the lubrication storage area. Additional site enhancement initiatives are underway.

Demonstrating its commitment to operational excellence, AG Lubricants recently installed a lubrication system at the client’s facility. This system uses Mobil Grease, known for its superior durability and performance, and provides proactive maintenance alerts to prevent grease shortages and reduce downtime.

One of the key factors in AG Lubricants’ selection as a preferred supplier was the proven performance of its product portfolio. Quaker Houghton, Mobil, and Centlube products, sourced both locally and internationally, have shown consistent reliability in demanding applications. Independent laboratory tests have demonstrated Quaker Houghton’s technical superiority, outperforming competitors in both longevity and performance.

Notably, the Quakerol HB Series hot mill rolling oil uses a proprietary blend of surface-active agents that form a sacrificial, conforming layer on work and back-up rolls. This chemistry reduces roll force, saves energy, and extends roll life, while improving surface quality and reducing rolled-in scale defects.

In addition, the Quintolubric 888 Series, a fire-resistant hydraulic fluid (FRHF), has proven ideal for high-risk environments. Free of water, mineral oil, and phosphate esters, this synthetic fluid delivers the anti-wear performance of premium hydraulic oils while being suitable for use in environmentally sensitive operations. It is compatible with hydraulic systems from all major manufacturers.

“The partnership showcases the powerful synergy between AG Lubricants’ expertise and the steel industry’s drive for excellence, together setting new standards for productivity, innovation, and operational success,” concludes Nell.